Processes are part of intellectual

property and among the most important assets of each organization.

As such, improving business processes is always a priority for

every organization.

This has been acknowledged

by business leaders across all industries. In the Gartner report

“Leading in Times of Transition: The 2010 CIO Agenda,” improving

business processes is ranked as the number one priority of CIOs

in 2007, 2008, 2009 and 2010.

Source:

Gartner EXP (January 2010) http://www.gartner.com/it/page.jsp?id=1283413

In the recent years Business

Process Management (BPM) has become the formal approach for managing

and improving enterprise processes.

BPM, as defined by Object

Management Group (OMG), is a holistic management approach that

promotes business effectiveness and efficiency while striving

for innovation, flexibility, and integration with technology.

Simply put, BPM attempts to improve processes continuously.

Every Business Process

Improvement initiative starts with capturing the processes as

they are, and then trying to optimize, automate and continuously

improving them towards perfection.

This paper provides an

overview and guidelines in taking inventory and modeling NPDI

processes within the BPM paradigm.

Introduction to NPDI

New product development and introduction, or NPDI, is about bringing

the right product to the right customers at the right time and

price.

NPDI is one of the most important processes in many companies as

it drives the revenue, margins and competitive position of a company

in the marketplace. Accordingly NPDI is always a target for Business

Processes Improvement.

Among others, the NPDI

process (or possibly the lack of it) can be responsible for:

-

Development of wrong product or service

- Schedule delays

- Cost overruns

- Feature set mismatch

- Marketing and sales performance issues

Various studies suggest

that between 50 and 80 percent of NPDI programs fail to live up

to management’s expectations. There are many reasons to it, such

as misunderstanding of real customers' needs.

The NPDI process starts

with identifying an opportunity in the market and ends with a

successful launch of the corresponding product or service. This

requires a coordinated effort among many functions, from marketing

to engineering and finance, to manufacturing, suppliers, business

development and sales.

Any miscommunication or

timing mismatch between those functions may result in extra costly

mistakes and delays. Utilizing BPM in NPDI can help in mitigate

many of possible problems sources, while making it more efficient.

Keep in mind: NPDI is a process, a journey, and not a destination.

While at its core NPDI represents one process, its actual activities

are executed in separate sequential or parallel processes.

All these processes need

to be synchronously managed between multi-disciplinary

teams to successfully bring a new product

to market, no matter if the product is an industrial machine with

hundreds of parts or a software system with different components

and modules.

To do so, first the underlying

processes need to be captured. The explicit definition of processes

not only facilitates continuous process

improvement cycles, but also helps with control, visibility and

knowledge retention within organizations.

Contrary to some depictions, being

process oriented doesn’t necessarily mean being rigid and prescriptive. Well

managed processes can anticipate and

provide agility and flexibility in adapting to market and requirement

changes, while fostering cross

functional harmony and effectiveness within organization.

NPDI Processes

The actual NPDI practice

is unique to every company due to its organizational structures,

available resources, information systems and overall capabilities.

Nevertheless the following model closely reflects an end-to-end

NPDI process.

Whether you use Stage-Gate,

PACE (Product And Cycle-time Excellence), DFSS (Design For Six

Sigma) or any other methodology, at the highest level the NPDI

process includes following core activities, each of which represent

a different aspect of NPDI.

- Project Selection

- Technical & Business Validation

- Development & Production

- Marketing & Sales Enablement

In the following sections we will break down and review each of

those aspects as individual subprocesses and activities.

To graphically represent process models all diagrams in this paper

are designed based on “Business Process Modeling Notation” (BPMN

2.0) standard.

For more details on BPMN

please refer to http://www.bpmn.org

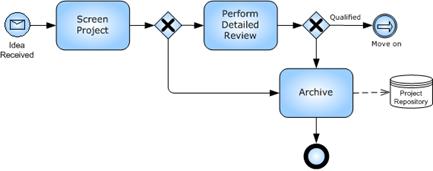

Project Selection

This is about selecting the idea that best aligns with business strategy and

objectives.

Sometime also referred

to as “Discovery and Scoping”, this includes activities such as

identifying opportunity, generating or soliciting product ideas,

screening, evaluating and scoring concepts, building business

case, estimating resource requirements and finally selecting a

project to pursue. The objective is to quickly find the closest

match and ensure the technical merits and alignment of market prospects of the project

with corporate strategy.

Depending on the industry

and the company’s culture this might be a predefined, scheduled

process or an on-demand basis - as shown in the sample flows below.

On-demand Model

Scheduled Model

One of the common problems

in this phase is that the selected project does not reflect the

real business objectives and strategy. Including process steps

to formally develop the selection criteria and enforcing the use

of these criteria throughout the process would prevent that type

of problems from happening.

In many BPM models top-level

activities can be decomposed into next level of detail or a “subprocess”.

The concept of subprocess manifests one of the key cornerstones

of BPM; reuse- and repeatability.

In the above example the

“prepare selection criteria” step can be modeled as a subprocess

like the one below.

In this case, for instance,

the same subprocess can also be used to drive M&A (Merger

and Acquisition) considerations.

Typically the selection criteria are defined as a weighted decision

matrix, which is beyond scope of this paper. [See KT (Kepner-Tregoe)

or AHP (Analytic Hierarchy Process) for more details]. A decision

model is used to ensure all objectives are satisfied according

to their importance.

The following example

helps to clarify the approach.

| Objective |

Weight |

Score |

| Profit Margin |

60 |

|

| Time to Market |

30 |

|

| Resource Requirements |

10 |

|

| … |

|

|

| Total |

100 |

|

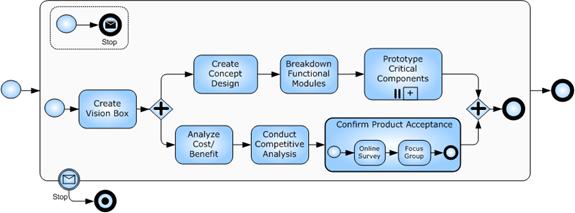

Technical and Business Validation

Validation is about proving

the concept, both on the technical and the business sides. In-depth

assessment of business viability and technical feasibility are

performed to ensure a valid business case, customer acceptance and financial merit to justify the project, resulting in a refined business plan, financial

projection, competitive positioning and technical requirements.

This phase includes activities

such as competitive analysis, focus group, prototyping, market

research, and maybe budget approval.

In this phase the most

common reasons for NDPI failure are a) the mismatch of product

features with customers’ real needs and b) underestimating the

challenges.

The most effective approach

for addressing those problems is to start with creating a “product

vision box” or “concept in context”. The purpose is to quickly

establish a shared vision among all stakeholders by spelling out

USP (Unique Selling Proposition), benefits, and positioning of

the new product. It will ensure that VOC (Voice of Customer) is

considered throughout the validation process and that challenges

are correctly assessed.

Depending on circumstances and resource availability activities might

be performed in parallel or sequential order. For example tight

engineering resources might result in a rewired process, in which

engineering engages only after business case is validated.

In either case the process can be stopped at any given point to save

time and resources.

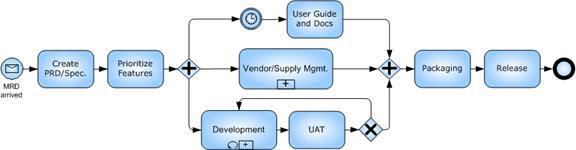

Development

and Production

Projects that match corporate

criteria and pass validation will move to the formal development

phase, where specifications are transformed into an actual product

for commercialization.

This starts with design specifications and production planning along with supporting

processes such as documentation, QA, packaging and ends with the

actual product ready for release. The production itself might

follow a formal methodology such as Scrum in software development

or Lean in manufacturing.

Typically in this phase problems happen due

to miscommunication, misinterpretation of requirements and change

management.

In many cases applying

an agile methodology to development process can prevent risk and

dramatically improve the project results. In an agile environment

the development is executed in an incremental and adaptive manner,

including a feedback loop with product management, as illustrated

below.

This approach can help

in minimizing misinterpretation and waste in course correction,

while providing product management with the flexibility to react

to market and requirement changes.

Course correction

approach in traditional vs. agile development process

Course correction

approach in traditional vs. agile development process

The actual development process can be broken down further into

specific activities for individual roles as demonstrated below

for a software product.

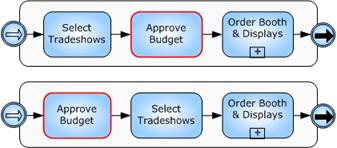

Marketing

The marketing process covers

activities involved in generating customer interest and demand,

starting from MRD (the Market Requirements Document) to actual

product launch and lead generation. This could include inbound

marketing, outbound marketing, branding and PR related activates.

In product marketing the

most common challenges are cost management (ROI), right targeting

and coordination with sales (imagine that the product is launched,

but inside-sales is not yet trained!).

While the above model might

closely resemble a typical marketing process, one model never

fits all. What if, for example, your organization decides to switch

from as-needed-basis to a fixed budget approach to marketing?

One of the central promises

of BPM is flexibility. In a process oriented environment such

changes are possible and as easy as switching the order of activities,

as illustrated in the following extract.

Key Performance Indicators

All along the NPDI process

execution monitoring relevant data and KPI (Key Performance Indicators)

can help in taking timely corrective actions to minimize cost,

while offering opportunities for process improvement.

One of inherent benefits

of BPM is the ease of access and tracking of KPIs. Applying BPM

principles allows you to define specific goals and means to measure

the performance of processes.

In an automated BPM environment (BPMS)

this can be easily done by non-intrusive interception of work,

which in addition to KPIs can help in risk management, Service

Level Agreement (SLA) and compliance monitoring. The

resulting data is typically available in real-time on management

dashboards as shown in above example.

Conclusion

Applying BPM concepts to

your business processes not only minimizes the common risks associated

with NPDI for current product pipeline, but also facilitates knowledge

retention and repeatable success for upcoming ones.

AUTHOR

Pejman Makhfi

Pejman is a Silicon Valley technology

veteran and serial entrepreneur with more than 18 years of progressive

experience in providing software expertise and best practices

to technology investors, business enterprises, and forward-thinking

startups.

Widely known as a leader in the field

of Business Process Management and Knowledge Modeling, Pejman

has been a key architect of multiple high-profile products, including

Savvion's award-winning BPM platform.

Today, Pejman is the VP of Solutions

at Savvion where he combines his decade of BPM experience with

his expertise as a PMP & Lean Six Sigma Black Belt to incorporate

continuous process improvement into the next generation of Life

Sciences, Banking and Telecom solutions.

His background includes:

CTO position at FinancialCircuit, a

company recognized as the technological innovator for financial

industry and awarded as Silicon Valley's Ninth Fastest-Growing

Private Company in 2003. (Acquired by LPL)

CTO and Director of Business Dev. at

TEN (The Enterprise Network), a top Silicon Valley technology

incubator hosting more than fifty Startups. Pejman managed TEN's

R&D as well as advised startups on the issues and trends affecting

early stage and emerging growth companies. TEN has helped launch

of many companies, including eBay, iPrint, Xros ad Vertical Networks.

Pejman holds a B.S./M.S. degree in

Computer Science from Dortmund University in Germany and is a

Scrum Master (CSM), an internationally certified Project Manager

(PMP) as well as a certified Lean Six Sigma Black Belt (SSBB)

in continuous business improvement.

He is the author of numerous patents and articles, including “Heptalysis

- a methodic approach to venture management” and

is an active contributor to organizations such as "American

Association for Artificial Intelligence" and "American

Society for Quality".

|